Overview

As an alternative to analyzing grape samples for their content of smoke related volatile phenols, grape samples can be fermented for use as a tool for the prediction of risk to wine quality from a smoke exposure in the vineyard. There are a number of available protocols for conducting fermentations in five gallon buckets, which will generally take 4-7 days and result in 3-4L of wine for sensory and chemical analysis.

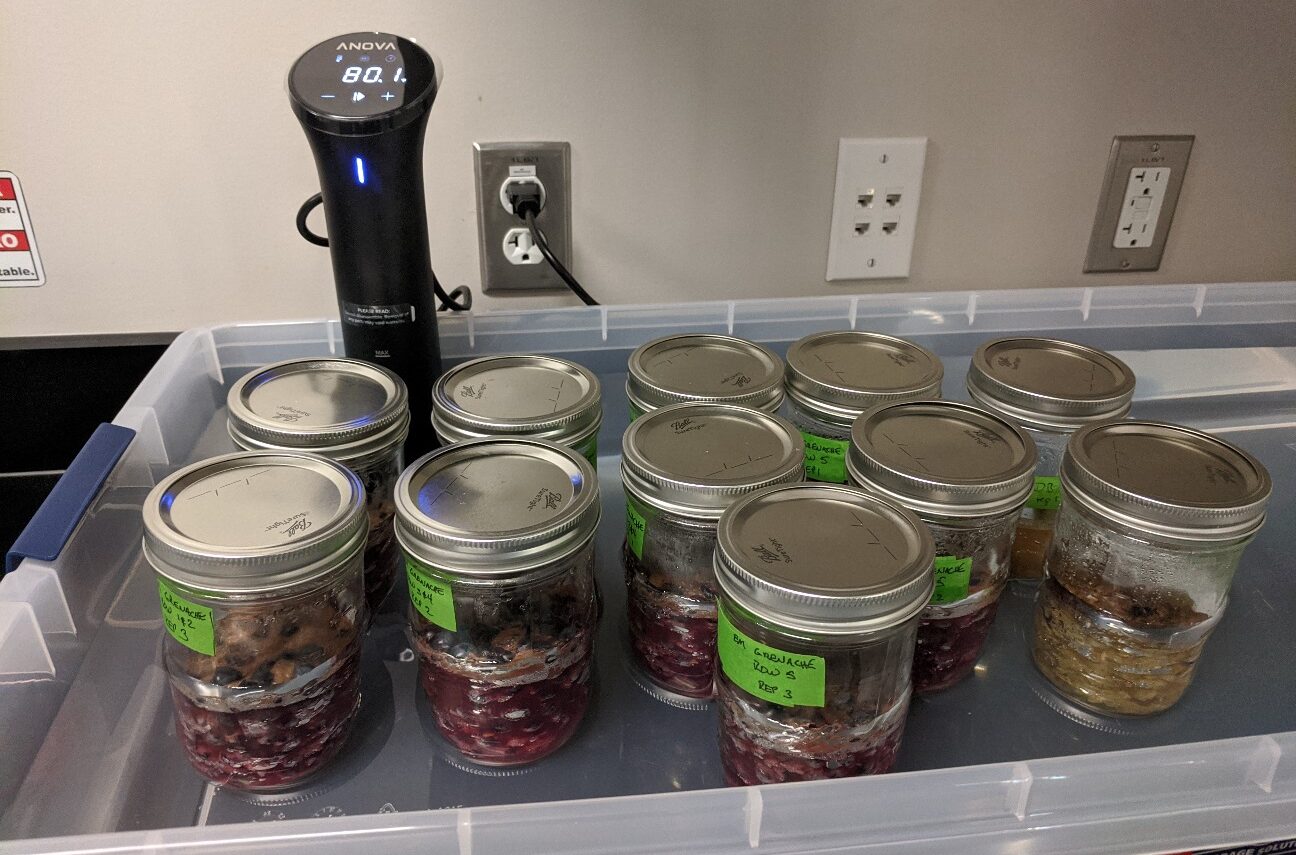

In an effort to reduce the amount of time required to conduct the fermentation, this protocol was developed for the use of glass canning jars as the fermentation vessel, with the addition of a water bath for temperature control to help increase the fermentation rate. Many winery labs will have access to a heated water bath which will typically hold four to six 16 oz. canning jars. If a water bath is not available or if space for more samples is needed, plastic storage containers can be substituted for the water bath, with a sous vide cooker providing the means to circulate temperature controlled water in the container. Using this approach, fermentations can be completed in as little as 36 hours.

Sample Collection

With the smaller fermentation volume in the canning jars, obtaining a representative sample of the vineyard block becomes critically important. In some cases, it will be useful to collect multiple samples from a block which can be fermented separately—this may be particularly useful in instances where a wildfire has burned near the vineyard—there may be a gradient of smoke exposure impact from the side of the block closer to the fire to the side of the block furthest from the fire. Even in the case of diffuse smoke from a distant source, it would be worthwhile to conduct replicate fermentations from individual blocks.

Collect samples as close to harvest as possible to provide a wine matrix similar to what would be expected at harvest

Collect samples using your normal protocol or a minimum 30-50 clusters per block (or sub-block if sampling for the presence of a gradient) otherwise

- Destem clusters into a bucket or other container, then remove any stems or MOG

- Crush the fruit with a manual crusher if available or with a potato masher or similar

- Add 50 mg/L KMBS (0.165 g per 10 lbs. of fruit) and mix thoroughly

- Transfer enough crushed fruit to three pre-tared canning jars per block (16 or 24 oz. jars are recommended) to fill the jars two thirds full; re-weigh the jars to determine the weight of must in each jar

- Collect an additional sample of the must for TA, pH and Brix analysis as well as an additional sample to freeze for later use as required.

- Adjust YAN level to 250 mg/L

Fermentation

- To prepare a yeast slurry for inoculation, multiply the number of 1.5 pint jars to be inoculated by 0.2. If using 1.0 pint jars, multiple the number of pint jars to be inoculated by 0.14. This is the number of grams of yeast to rehydrate.

- Suspend the yeast in !0x the weight of 105F water. EC1118 is recommended for rapid fermentations. If desired, use the yeast strain that would be used in normal production practice for the grape variety.

- After ten minutes, add an equivalent volume of grape must to the yeast slurry to bring the temperature of the yeast slurry down closer to that of the must. Repeat as necessary at 10 minute intervals until the temperature of the slurry is within 10 degrees of the temperature of the must.

- Divide the slurry across the set of canning jars to be inoculated. Mix the inoculation into must with a spoon, or by putting a lid onto the jar and inverting it several times.

- Place the jars into an appropriately sized storage container, then fill the container with warm water until the level is about two-thirds of the way up the container.

- Following the manufacturer’s instructions set the temperature of a sous vide machine to the desired temperature (85-87F is recommended), then place sous vide machine into the water bath. Most sous vide machines have a clip that can be connected to the side of the water bath.

- Canning jar lids and rings should be placed on the jars loosely, to avoid a pressure build up in the jar during fermentation.

- 2-3 times daily, remove jars one by one, tighten the lid, then invert the jar several times to mix the cap with the fermenting wine. Remember to loosen the lids prior to returning the jars to the water bath.

- Most sous vide machines have a low water level safety system which turns the machine off if the water level drops below a set limit. These safety systems can sometimes be activated during “pumpovers”, so check to ensure the sous vide system is running after all the jars have been returned to the bath. Periodically add more warm water if the level drops through excess evaporation.

- Brix measurements and smelling/tasting the fermentation should be done daily during the mixing session.

Pressing

- When fermentations have completed (typically ~48-60 hours), the canning jar fermentations can be poured into a stainless steel strainer and pressed gently by hand to extract as much liquid as possible.

- The pressed wine can be decanted to smaller canning jars or other appropriately sized bottles to finish fermentation if necessary or for chemical analysis/sensory evaluation.

- A subsample of each fermentation can also be frozen for later use to support insurance claims or for later analysis if lab capacity is constrained during a large smoke event.

Sensory evaluation

- Nano-scale fermentations are designed to provide enough wine to support multiple tastings; if possible, 2-3 people should evaluate each wine separately.

- Wines should be smelled for any off aromas related to smoke

- It may be necessary to add small amounts of copper sulfate (0.1 ppm) to newly fermented wines if hydrogen sulfide is present. The copper addition should diminish the masking effect of H2S.

- After smelling, wines should be tasted, with emphasis on the evaluation of the after-taste of the wine, which may be bitter or there may be smoke related flavors that develop after the wine has been tasted.

- If multiple wines are being evaluated allow sufficient time between samples to allow the aftertaste from previously tasted wines to diminish. There is a strong carryover effect from many smoke affected wines that may affect the evaluation of subsequent wines.

- If multiple people are tasting, it may be useful to evaluate the wines in a different order as a way to manage the carryover effect.